Earth Day at Tek Pak: Shaping A More Sustainable Future

The thermoforming industry, responsible for everything ranging from food packaging, small electronics shields, and even medical trays, has been...

2 min read

Tony Beyer

:

Oct 24, 2023 1:55:15 PM

Tony Beyer

:

Oct 24, 2023 1:55:15 PM

Sustainability has become a significant initiative for all businesses in today's quickly changing manufacturing industry. This includes the widely utilized thermoforming manufacturing process, which produces various plastic packaging products for the food service, medical, electronics, and industrial arenas. By lowering waste, energy use, and environmental effects, the incorporation of intelligent automation in thermoforming can significantly increase sustainability. In this blog, we will examine how intelligent automation is improving thermoforming manufacturing and making it more efficient and environmentally friendly in this blog.

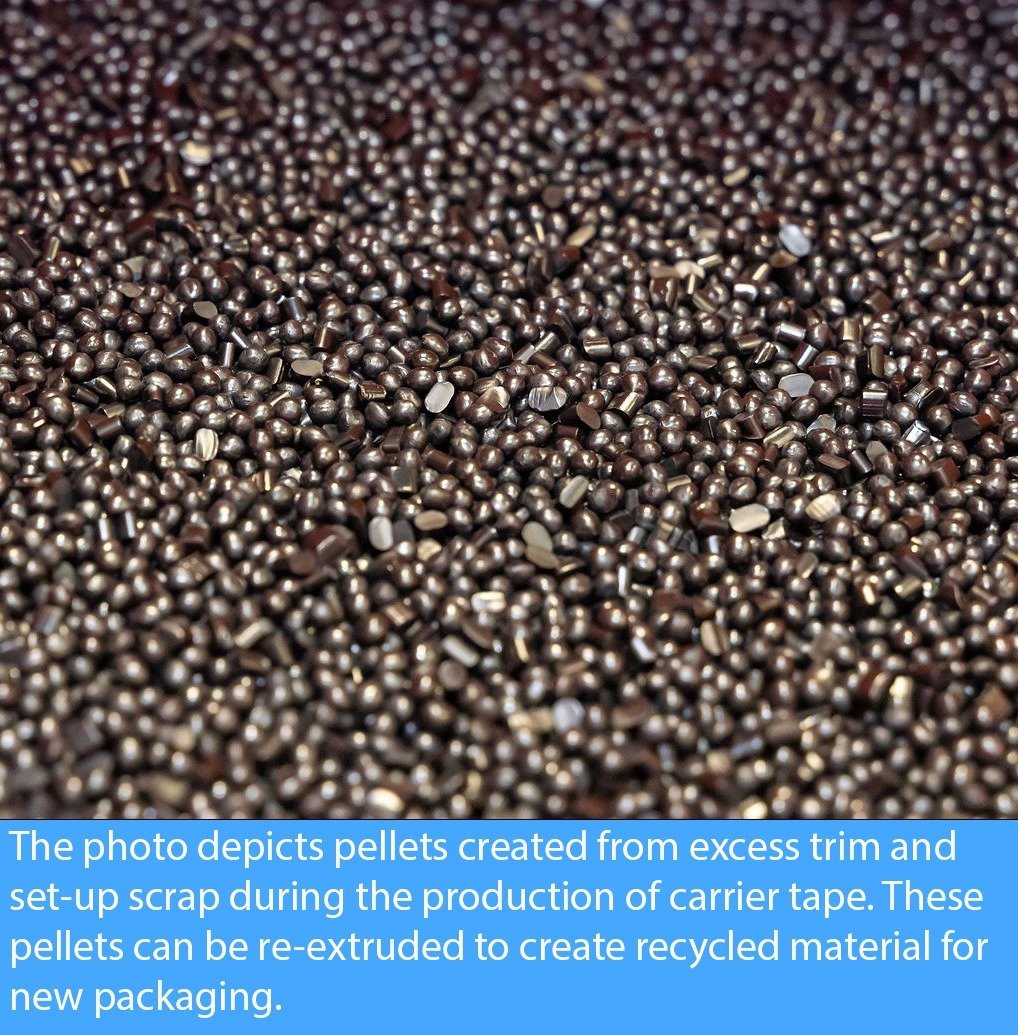

Reducing material waste is one of the main ways intelligent automation improves sustainability in thermoforming manufacturing. Traditional thermoforming techniques frequently produce a significant proportion of scrap material. Intelligent automation improves accuracy and consistency significantly. Tek Pak has always been an on-demand supplier. Customer product is not stored, and we work very hard to stay current with our customers' needs.

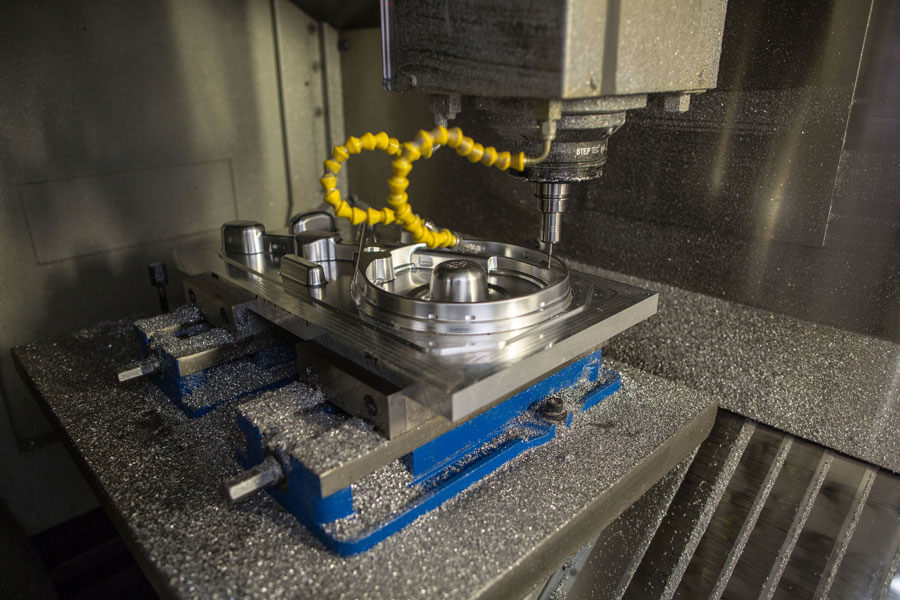

Automated systems with cutting-edge sensors and machine learning algorithms can determine the precise amount of material required for each product, optimizing material utilization. This waste reduction contributes to a greener and more sustainable production process by reducing the amount of non-recyclable or hard-to-recycle plastic trash that is disposed of and saving essential resources.

Systems for intelligent automation are made to run as energy-efficiently as possible. They can minimize energy usage during thermoforming by optimizing the heating and cooling processes. To reduce energy loss, automated systems, for instance, can monitor temperature and instantly alter it according to the particular material being utilized. Automated shut-off methods can guarantee that equipment is only running when required to conserve energy further.

Lowering energy use lowers the industrial process's carbon footprint and operational expenses. Consequently, this leads to a production process that is more ecologically friendly and sustainable.

In thermoforming manufacturing, intelligent automation improves the consistency and quality of the final product. Real-time defect and inconsistency detection is possible with automated equipment through the use of computer vision systems and real-time monitoring. This lowers the possibility of creating mediocre or flawed items, which lessens waste. Reducing the amount of things thrown away saves resources and improves sustainability overall. Tek Pak continues to upgrade equipment and employee competency with more automated robotic systems to keep Tek Pak personnel updated on the latest and greatest automation and sustainability efforts.

The benefits of intelligent automation are extended into the supply chain from the manufacturing floor. Advanced data analytics and networked technologies enable manufacturers to understand their materials and operations more deeply. This results in less waste in the supply chain, more effective transportation, and better inventory management.

Manufacturers of thermoforming products can lessen their environmental effects and the total carbon footprint of their activities by streamlining the supply chain.

Increased personalization in thermoforming production is made possible by intelligent automation. As a result, businesses may create goods specifically suited to their client's demands, preventing overproduction and cutting down on the waste that comes with having too much inventory.

Another way Tek Pak is meeting the demands of intelligent automation while at the same time surpassing client expectations is by expanding their workforce. Tek Pak offers an Apprentice Program to provide aspiring thermoforming team members with hands-on experience and mentorship opportunities, affording all participants access to a vast knowledge base and a deep bench of thermoforming experts. Our growth dictates the need to find employees who are willing to learn while they earn.

In thermoforming manufacturing, intelligent automation is bringing in a new era of sustainability. Intelligent automation is changing the industry to be more efficient and environmentally beneficial by decreasing material waste, increasing energy efficiency, improving quality control, streamlining the supply chain, and providing greater customization.

Manufacturers of thermoforming products like Tek Pak, Inc. use these cutting-edge technologies to gain not just from lower costs and greater competitiveness but also from a greener and more ecologically conscious future, as long as sustainability remains a top priority for society. Embracing intelligent automation benefits the environment, humankind, and communities alike.

Our commitment to our clients is to provide them with high-quality and innovative thermoforming solutions, and we would love to discuss your packaging needs. To get started, you can visit our contact page, give us a call, or request a quote.

The thermoforming industry, responsible for everything ranging from food packaging, small electronics shields, and even medical trays, has been...

The world of electronics relies on countless tiny components, from resistors to integrated circuits, that work together to power our devices. But...

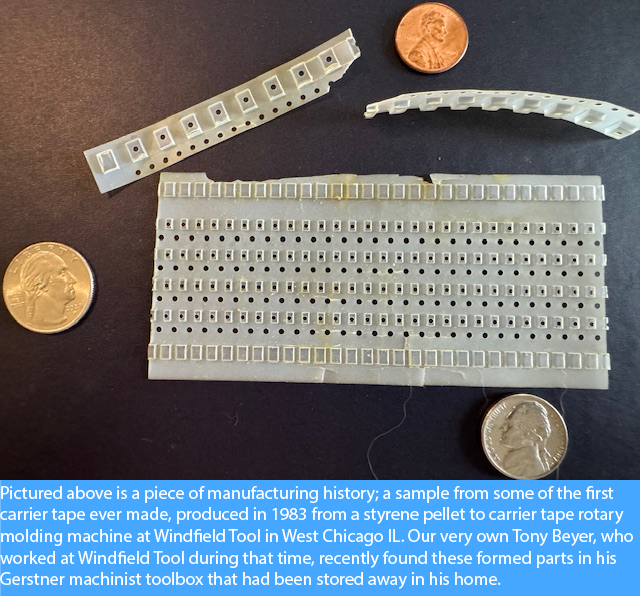

Thank you to everyone who took time out to vote for Tek Pak’s Carrier Tape nomination in the Illinois Manufacturers’ Association’s (IMA) annual “...