Thermoforming Tooling

Custom Solutions

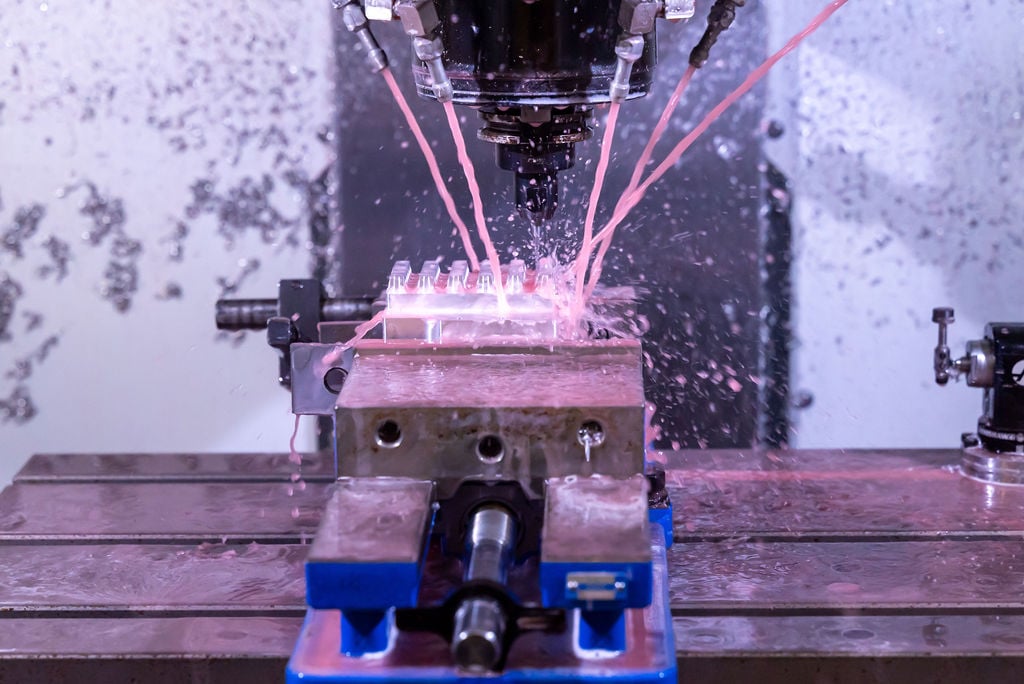

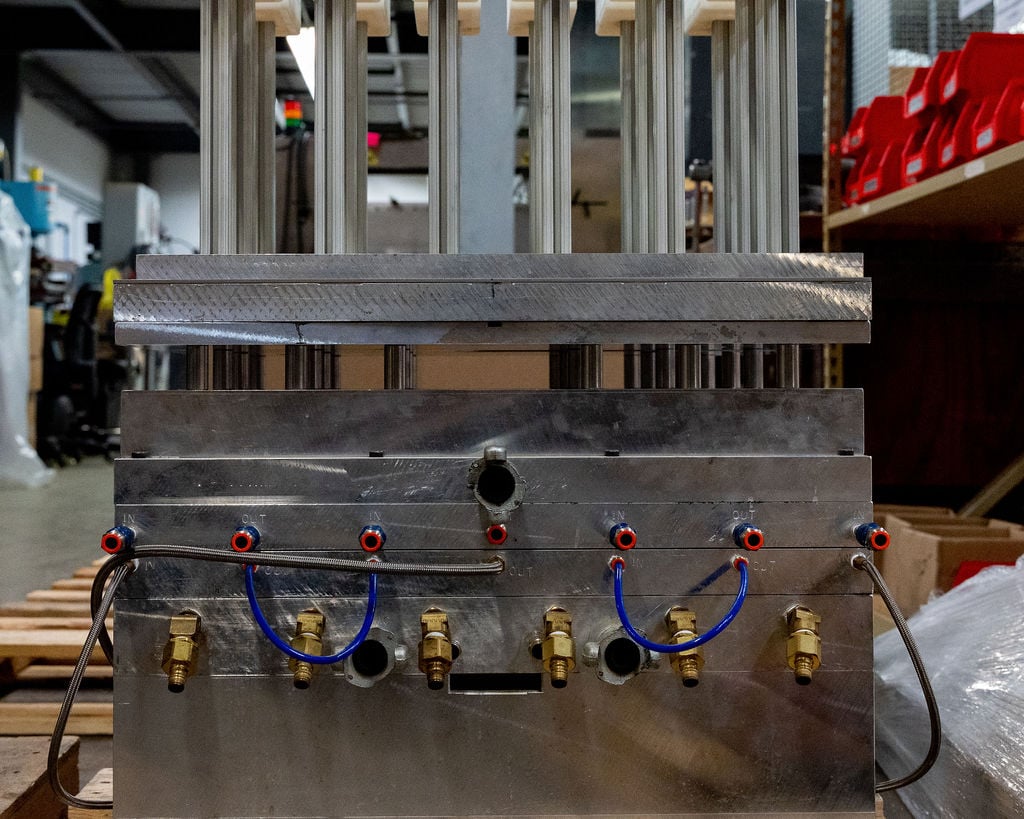

Tek Pak provides machining, thermoform tool design, tool fabrication, as well as tool testing for high-performance products and packaging. Our team collaborates with customers to design and build tools based on their specific requirements, whether that is a single cavity prototype tool or a multi-cavity high-performance production tool. Features found in our high-performance production tools include water-cooled cavities, moving plug assist, air-actuated temperature-controlled strippers and sheet clamps, as well as end-of-machine automation and stacking. We are experts at providing custom solutions that quickly resolve our customers’ production and packaging challenges. Tek Pak is proud of our industry-leading turnaround times. We can do thermoform tray design through a dozen sample parts in 3 weeks or less.

Thermoform Prototype Trays

When it comes to the production of thermoform trays, prototypes always come first. Whether you have a custom design for your tray or you need Tek Pak to design a tray to fit your parts, we can get it done in record time. Our prototype molds are run-tested in production-level thermoform machines capable of 100 PSI pressure forming. We can form the following materials: polypropylene, Polyethylene, Styrene, RPET, APET, Ultem, multilayered materials, and laminated materials, in thicknesses from .005 to .070 inches thick. All prototype molds are machined from aluminum to give production-level form, fit, and function.

Beyond Machining

Tek Pak is not just a standard tool shop, we offer services beyond machining. Tek Pak offers support in product and packaging design, tool design, fabrication and tool testing.

Tek Pak’s experienced team will work with you to design and build tools based on your requirement, whether that is a single cavity prototype tool or a multi-cavity high-performance production tool.

The Best Features

Features found in high-performance production tools.

- Water-cooled cavities

- Moving plug assist

- Air actuated temperature-controlled strippers

- Individual air actuated sheet clamps

- End of machine automation/stacking

Expert Engineers

Our talented engineers will design any component for your equipment. Some examples of the benefits of working with the experts at Tek Pak: master tooling/quick-change systems, interchangeable family tooling, and complete custom tools that feature: pressure boxes, mold plates and cooling plates, and trim platen tools.

Unmatched Versatility

Our versatile tool shop can handle micromachined components all the way up to 60” long X 40” wide X 20” deep.

Tek Pak uses an array of plug assist products to enhance the forming process based on the type of material to be formed. During the design process, we will help you select the correct material to meet your needs.

Want to Talk?

Our knowledgeable staff is available to answer your technical questions, provide quotes, and coordinate your designs with our engineering staff. Please call us at: (630) 406-0560, or if you like please fill out the form on this page.